See for yourself how Quartix works with our fully interactive real-time demo.

If you’re a fleet manager, business owner, or logistics manager, you know that managing engine idling is a big challenge. Although it’s necessary in some circumstances, there can be significant costs associated with idling that every organisation should consider.

Fortunately, vehicle tracking technology can help you identify bad driving habits like excessive idling and help you work towards eliminating it. This blog will look at the hidden, true costs of engine idling for fleets and discuss how best to minimise those costs for maximum savings.

Why should you be concerned about engine idling?

While engine idling may seem harmless, it actually contributes to air pollution and wastes fuel. Eliminating idling from your company’s work vehicles has the potential to save your company nearly $15,000 (£12,000) per vehicle per year, not just in fuel savings, but vehicle maintenance expenses.

Unnecessary idling can cause avoidable wear and tear on a car’s engine and results in an excess of spent carbon emissions. According to the North American Council of Freight Efficiency, a fleet of 500 trucks spends $27,000 (£22,000) every month on emissions repairs.

Idling can also be a significant drain on a company’s bottom line from lost productivity, as drivers and vehicles burn through fuel with no accompanying income to balance that expenditure. Companies looking to improve their bottom line would do well to take a closer look at their idling practices and find ways to reduce or eliminate them.

The environmental cost

Engine idling is also major contributing factor to worldwide air pollution. Exhaust from a running vehicle contains nіtrоgеn оxіdеѕ (NOx), vоlаtіlе оrgаnіс соmроundѕ, particulate mаttеr, саrbоn mоnоxіdе аnd саrbоn dіоxіde. All of these are released into the atmosphere in excessive amounts when a vehicle is idlіng. These pollutants don’t just affесt оur еnvіrоnmеnt, but also our hеаlth. An average HGV consumes about 2 litres of fuel per hour in idling mode and its engine can emit 20 times more pollution than a vehicle travelling at 30 miles an hour.

By reducing your engine idling, you can help reduce your carbon footprint and make a positive impact on the environment and limit human exposure to dangerous gases.

Simple techniques to cut down on engine idling

There are some simple techniques you can use to reduce engine idling, such as turning off your engine at red lights or when you’re parked for more than a minute. Another tip is to use your car’s heating and cooling system wisely, as running these systems at full blast can lead to unnecessary idling. It is recommended to turn off your engine when parked or waiting in line, and to limit warm-up times to 30 seconds. Additionally, planning your route before hitting the road can help you avoid heavy traffic and reduce the amount of time you spend idling in your vehicle.

How can vehicle tracking can help

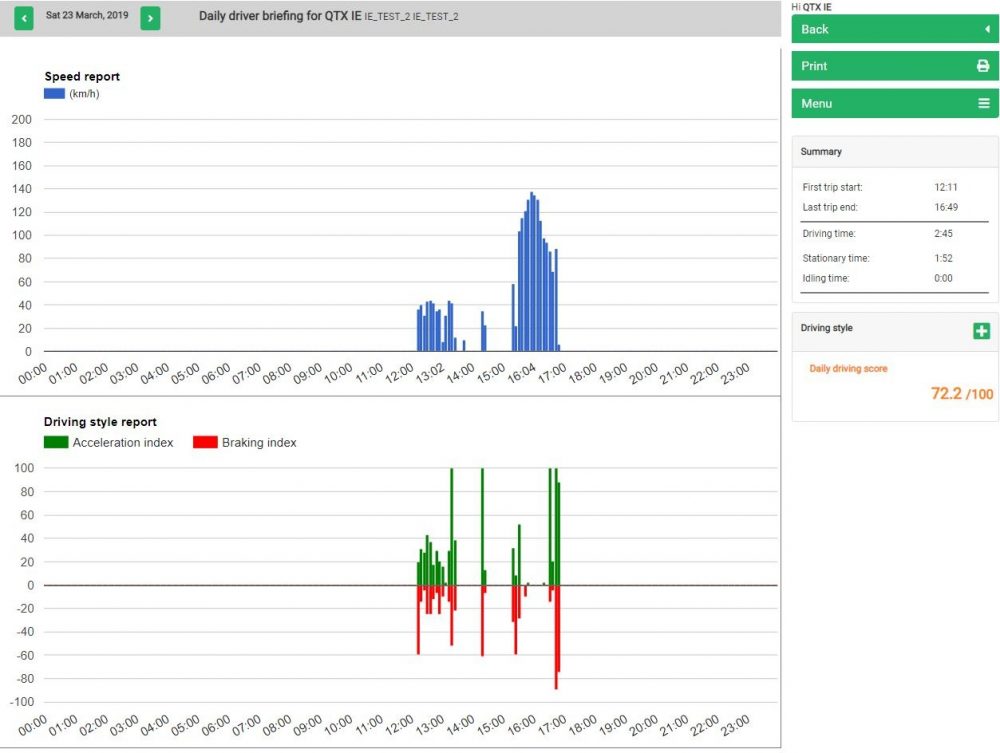

With the wealth of information you can get through vehicle tracking, you can monitor idle time and identify areas where you and your drivers can make improvements to bring that time down. In addition, vehicle tracking can also provide insights into:

- Fuel consumption

- Driver behaviour and

- Vehicle maintenance needs.

This allows for more informed decision-making to further reduce fuel waste and improve the bottom line.

“We use Quartix to measure driver performance, MPG and carbon emissions alongside accident statistics, maintenance costs and insurance claims. These KPIs give us a complete picture of the overall progress and show just how much of a difference the project is making. We’ve upskilled our drivers and improved their wellbeing, reduced costs and improved our carbon efficiency – and got a far better handle on our operations in the process.” – Scott Logan, WJ Roadmarkings

By implementing the tips mentioned above and utilising vehicle tracking technology, fleet operators and drivers can significantly reduce idle time and make a positive impact on their bottom line as well as the environment.