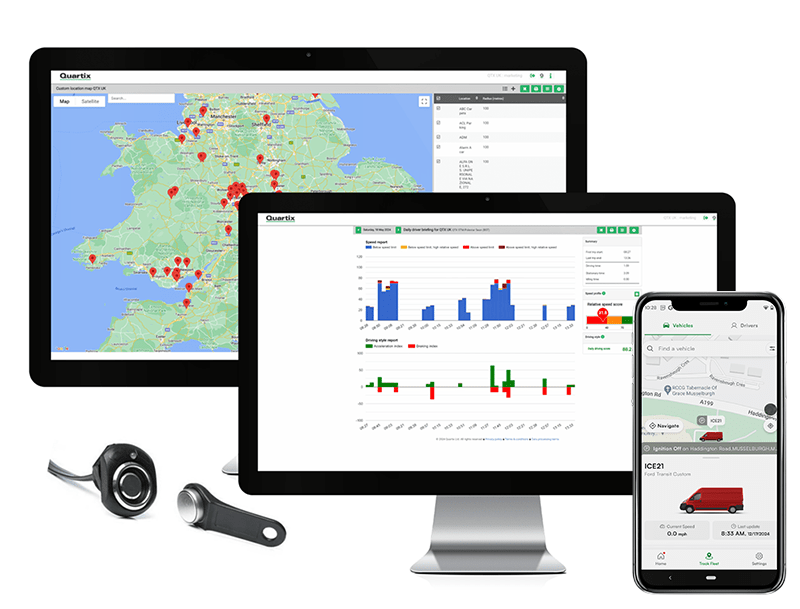

See for yourself how Quartix works with our fully interactive real-time demo.

TL;DR

Maintaining the correct temperature during transport is essential for preserving perishable food, pharmaceuticals, and other temperature-sensitive goods. Even minor fluctuations can lead to spoilage, compliance breaches, and financial losses.

This guide explains how real-time temperature monitoring using sensors, data loggers, and fleet tracking systems helps businesses to:

- Detect temperature deviations early to prevent waste

- Ensure compliance with industry regulations

- Receive instant alerts for temperature fluctuations

- Improve supply chain efficiency with live tracking and automated reporting

Whether you run a small catering business or manage a nationwide logistics operation for pharmaceuticals, FMCG, or industrial supplies, temperature monitoring technology helps safeguard your goods, ensure compliance, and enhance customer satisfaction by preventing losses and maintaining quality throughout transit.

Hear how National Veterinary Services and Reynolds Catering Supplies are using Quartix fleet tracking with integrated temperature readings to ensure product quality.

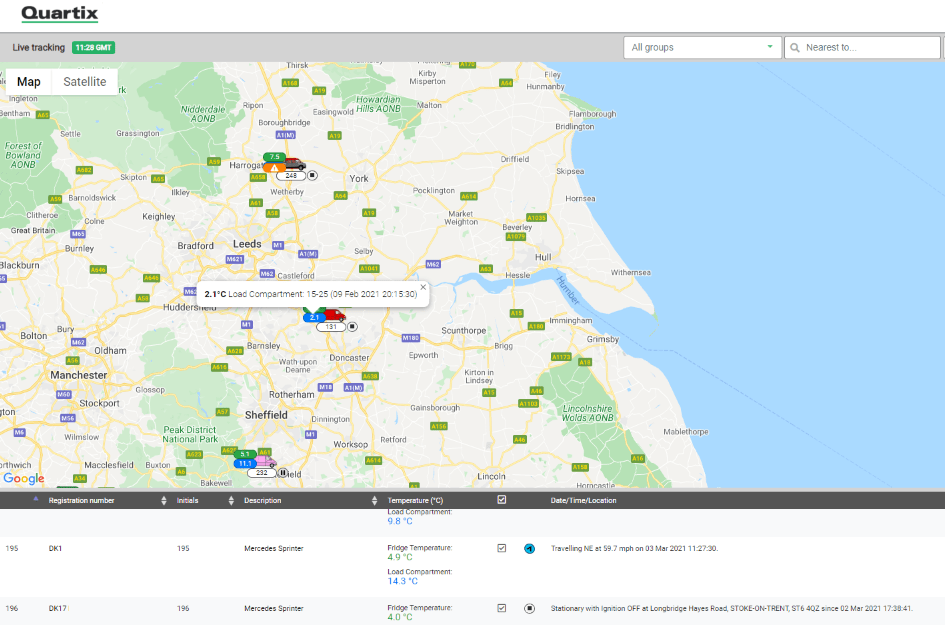

See live vehicle location and temperature status in one view. Learn more about our Fleet Tracking Temperature Monitoring Add-On.

Temperature-Controlled Transport

Transporting temperature-sensitive goods comes with a unique set of challenges. Whether you’re a small business delivering perishable food, or in charge of a nationwide logistics operation for pharmaceutical supplies, maintaining the correct temperature for your product is critical. Even minor fluctuations can result in spoilage, lost revenue, and compliance breaches.

In this guide, we’ll break down everything you need to know about temperature-controlled transport, from understanding the risks to implementing the best monitoring solutions for your vehicles.

Why Temperature Control Matters

Temperature-sensitive goods must be kept within specific temperature ranges to remain safe and effective. Whether it’s fresh produce, vaccines, or chemicals, changes in cargo temperature can result in:

- Spoilage and waste – leading to lost stock and revenue

- Compliance violations – breaching industry standards

- Customer dissatisfaction – failed deliveries that impact your future business

Ensuring stable temperatures during transit minimises the risk of product degradation, financial losses, and compliance failures (such as meeting regulatory standards including Hazard Analysis and Critical Control Point (HACCP) set by the Food Standards Agency.

Real-time temperature monitoring helps companies to:

- Maintain product quality by detecting temperature deviations early.

- Comply with industry regulations and standards such as HACCP.

- See live updates of your supply chain operations and prevent costly delays.

- Automatically log data for audits and proof of regulatory compliance.

- Exceed service delivery targets and delight your customers.

Industries that Depend on Temperature-Controlled Logistics

Food & Beverage

Fresh produce, dairy, frozen foods, seafood, wine

Pharmaceuticals & Healthcare

Vaccines, insulin, blood samples, biologics

Chemicals & Industrial Products

Laboratory reagents, adhesives, industrial liquids

Electronics & High-Tech Goods

Batteries, semiconductors, LCD screens

Standards for Temperature-Controlled Transport

Ensuring compliance with UK regulations is essential for businesses transporting temperature-sensitive goods. Here are the key standards governing food, pharmaceuticals, and perishable products in the UK:

Good Distribution Practice (GDP – MHRA)

Regulates pharmaceutical transport and storage, ensuring medicines are maintained under the right conditions. The GDP is overseen by the Medicines and Healthcare products Regulatory Agency (MHRA). See MHRA website

Food Safety & Hygiene (England) Regulations 2013

Requires perishable foods to be transported at safe temperatures (e.g., chilled below 8°C, frozen at -18°C or below). Based on EU Regulation (EC) No 852/2004 and enforced by the Food Standards Agency (FSA). See FSA website

BRCGS (British Retail Consortium Global Standards) for Storage & Distribution

A certification standard ensuring best practices for temperature-controlled storage and transport. BRCGS is widely used in food, pharmaceuticals, and consumer goods logistics. See BRCGS website

ATP Agreement (Perishable Food Transport Standards)

Regulates refrigerated vehicles and temperature-controlled food transport for both domestic and international shipments. UK businesses must comply with these technical vehicle standards under the UNECE Agreement on the International Carriage of Perishable Foodstuffs (ATP). See ATP website

By following these regulations, businesses can ensure compliance, maintain product integrity, and improve supply chain efficiency.

Cold Chain vs. Heat-Sensitive Goods

Not all temperature-sensitive goods require refrigeration. Some need to be kept cool, while others must be protected from freezing temperatures.

Cold Chain Goods

Require refrigeration or freezing

These items must stay within low-temperature ranges to prevent spoilage or loss of effectiveness.

- Food & Beverage: Dairy, frozen foods, fresh produce, seafood

- Pharmaceuticals & Medical Supplies: Vaccines, blood samples, insulin

- Chemicals & Cosmetics: Laboratory reagents, adhesives, beauty products

Typical Temperature Ranges:

- Frozen goods: -18°C and below

- Chilled goods: 0°C to 5°C

- Pharmaceuticals: 2°C to 8°C

Heat-Sensitive Goods

Spoil if they drop below a certain temperature

Some products degrade or become damaged if exposed to freezing conditions.

- Pharmaceuticals: Certain medicines lose their effectiveness when frozen

- Beverages & Food: Wine, oils, some fruits & vegetables

- Electronics & Industrial Goods: Batteries, adhesives, some chemicals

Typical Temperature Ranges:

- No-freeze zone: 5°C and above

- Industrial products: 10°C to 25°C

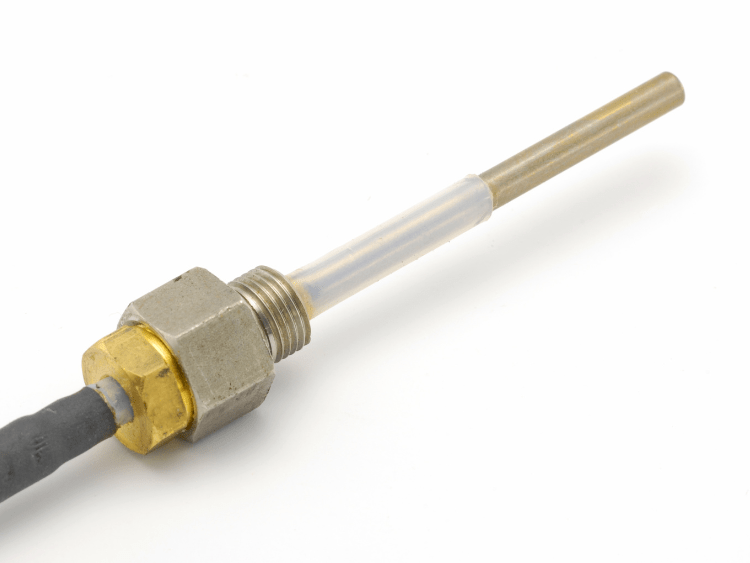

How Vehicle Temperature Monitoring Works

Real-time temperature monitoring uses sensors and tracking software to keep shipments within safe temperature limits. Key components include:

- Ambient temperature sensors and thermometer probes measure air temperature inside the cargo area.

- Temperature data loggers to keep record of temperature fluctuations.

The Role of Temperature Data Loggers

A temperature data logger is a device that continuously records temperature variations inside a transport vehicle or storage unit.

These devices are essential if you need to:

- Track temperature fluctuations throughout a journey

- Provide compliance-ready reports for audits and inspections

- Analyse trends and identify risk areas

- Automate alerts when a threshold is exceeded

- Store historical data for compliance and performance analysis

- Integrate readings with GPS fleet tracking for complete visibility

Live Fleet Tracking with Integrated Temperature Readings and Alerts

Temperature monitoring probes can be connected to fleet tracking devices to provide:

- Live location and temperature status displayed within the fleet management dashboard

- Instant notifications for temperature deviations

- Custom temperature thresholds for different types of cargo

- Email, SMS, or fleet dashboard alerts triggered when temperature drops above or below the safe threshold

- Seamless reporting of goods transportation and temperatures

Learn more: Fleet Tracking with Integrated Temperature Monitoring

Example Scenarios:

Cold chain breach: A vaccine shipment rises above 8°C → Alert sent → Route adjusted to nearest cold storage facility.

Freezing risk: A wine delivery drops below 5°C in winter → Alert sent → Insulation adjusted to protect cargo.

Refrigeration failure: Cooling system malfunctions → System detects rising temperature → Driver and fleet manager notified.

For safety-critical products, integrating temperature monitoring with fleet tracking offers an extra layer of protection, providing real-time alerts and seamless compliance reporting. However, a separate primary monitoring solution may be required for closer supervision of regulated or high-risk goods. But with temperature data available directly on your fleet tracking dashboard, monitoring conditions has never been easier, giving you both convenience and peace of mind.

Case Study: NVS Veterinary Supplies

The UK’s largest veterinary wholesaler, National Veterinary Services Ltd (NVS), provides veterinary surgeons with a variety of goods, including temperature-controlled items such as medicines, vaccines, and animal food.

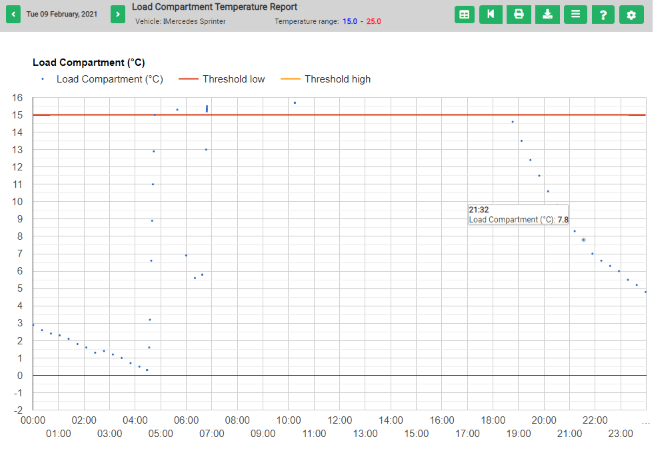

To ensure regulatory compliance and deliver top-quality products to their customers on a next-day service, NVS needed a reliable, efficient, and cost-friendly way to monitor the temperatures in their fleet of over 150 vans in real-time. As long-time customers of Quartix, they could easily add this to their fleet tracking solution.

“Quartix allows us to monitor the fleet effectively and ensure the load compartments and fridges remain temperature compliant. When our customers receive their orders, they can be confident that the goods have been transported under correct conditions.”

Case Study: Reynolds Maintains Food Quality

Reynolds Catering Supplies is a leading fresh food supplier to the UK food service industry. Since 2011, Reynolds has used Quartix to track its competitive, nationwide logistics operation.

Reynolds’ Head of Fleet Support, Steve White, explains, “We looked for ease of use, best price point and wide-ranging capabilities. From an operational perspective, live tracking has enabled us to manage delivery schedules and the effective re-routing of drivers”.

Reynolds’ need to monitor the temperatures of their climate-controlled vehicles was easily catered for with Quartix Temperature Monitoring. Two probes per vehicle alert Reynolds to variances of just 0.5° C outside a custom temperature range, triggering an email to warn staff of potential product loss. Prior to the implementation of this technology, checks were performed manually by drivers, a process that was time-consuming and prone to error.

“The Quartix tracking system gives us a full chill-chain audit, whereby we can verify the status of the load at any time. This has resulted in less wastage, improved customer service and helps document compliance with Food Safety and Hygiene Regulations.”

Common Cold Chain Challenges & How to Overcome Them

Refrigeration Malfunctions

- Risk: A faulty refrigeration unit can quickly cause spoilage.

- Solution: Use real-time temperature monitoring and alerts to detect failures early.

Supply Chain Delays

- Risk: Unexpected delays can leave shipments exposed to unsafe temperatures.

- Solution: Live fleet tracking helps plan alternative routes and manage delays effectively.

Compliance & Auditing

- Risk: Many industries require strict temperature records for safety and legal reasons.

- Solution: Automated data logging keeps a full history of temperature readings, providing proof of compliance.

Best Practices for Temperature-Controlled Transport

Pre-trip equipment checks

Ensure refrigeration units and sensors are working properly

Set custom temperature thresholds

Configure safe ranges for each product type

Train drivers how to respond to alerts

Quick action can prevent losses

Use data to improve performance

Identify trends and optimise delivery routes

Ensure Safe Transport of Temperature-Sensitive Goods

Whether you’re a small business managing a local delivery route or a fleet manager overseeing nationwide logistics, keeping goods at the right temperature is essential. With real-time tracking, instant temperature alerts, and automated reporting, you can prevent spoilage, reduce losses, and stay compliant.

See Live Vehicle Location and Temperature Status in One View

Looking to improve your fleet’s temperature monitoring capabilities? Discover how Quartix’s real-time tracking and temperature monitoring can help protect your sensitive cargo.