See for yourself how Quartix works with our fully interactive real-time demo.

Low rolling resistance tires are tires that are designed to save fuel by reducing the amount of energy lost as heat through friction between the tire and the road.

Due to their ability to improve fuel economy, these tires are often marketed to fleets, as the accumulated fuel savings of kitting out a large number of vehicles with these tires can be significant.

Although low rolling resistance tires can improve a vehicle’s fuel economy around 3-10%, they are around 50% more expensive than standard tires. Such tires are therefore an upfront investment that (hopefully) pays for itself over time.

To help you avoid potentially wasting money on low rolling resistance tires when your fleet does not actually need them, we spoke with Mike Skoropad from tire retailer United Tires to look at the factors that can affect the potential ROI of low rolling resistance tires.

1. The amount you can afford to invest initially

Low rolling resistance tires are a relatively new technology, only being developed in the 1990s.

The design and manufacturing that goes into these tires has grown in sophistication rapidly over the last 30 years, and with so many low rolling resistance tires on the market nowadays, there is a huge difference in quality between the more expensive and more affordable tires on the market.

There are essentially two ways that low rolling resistance tires are produced. More affordable tires are simply made with lower tread depth than standard tires, meaning that there is less grip and friction between the tire and the road (thus lowering resistance).

More expensive tires, on the other hand, are manufactured with certain materials that reduce resistance without sacrificing tread depth.

Lower tread depth means that tires offer less traction and need to be replaced more regularly than standard tires. Investing in cheaper low rolling resistance tires is therefore a false economy.

If you are going to kit out your fleet with low rolling resistance tires, first ensure that you can afford the more state-of-the-art tires. Look for tires manufactured with silica, as these tend to offer reduced rolling resistance by virtue of their material rather than their reduced tread depth.

2. What proportion of your fleet’s operating costs is spent on fuel?

Since switching to low rolling resistance tires can eat up a large chunk of your budget, you need to work out what priority lowering fuel economy is for your fleet.

Typically, fuel costs account for 60% of a fleet’s total operational costs. If your fuel expenditure is significantly higher than this (say over 65%) then switching to low rolling resistance tires makes sense.

If however, your fuel costs run under this, then you may well save more money by investing elsewhere.

3. Your fleet’s average speed

Low rolling resistance tires offer the biggest fuel savings when they are being driven on at high speeds.

The tires lower the amount of energy lost as heat between your tires and the road. Driving at higher speeds increases the amount of energy lost as heat in this way, so low rolling resistance tires are most effective in these conditions.

Before investing in low rolling resistance tires, you should therefore know the average speed that your vehicles travel at. If your fleet does most of their miles on motorways, then low rolling resistance tires make sense. If they spend a lot of time in traffic in cities, then you are unlikely to get the required savings needed to make these tires a worthwhile investment.

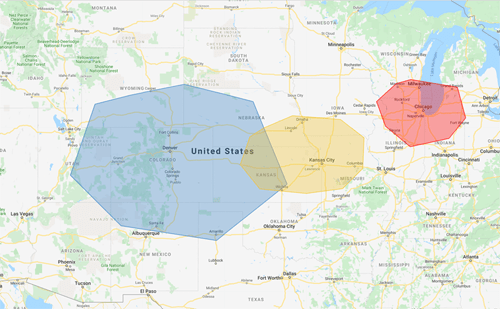

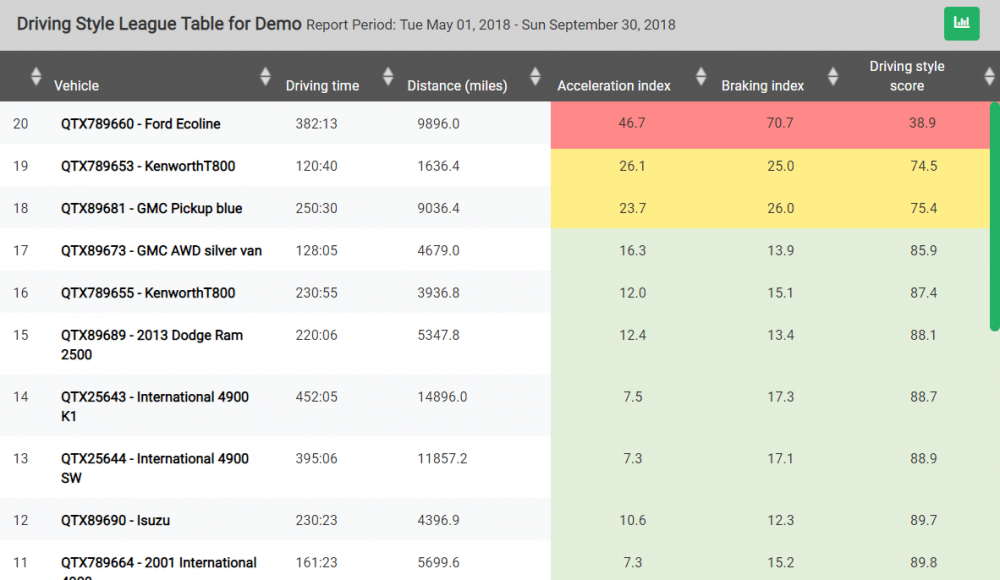

Tracking your vehicles can help you identify the average speed that your fleet travels. It can also highlight congested portions of journeys and therefore enable you to optimize your routes and maximize money saved from low rolling resistance tires.

4. Your fleet’s maintenance costs

Low rolling resistance tires are, in general, less durable than standard tires. In particular, they need more frequent retreading than standard tires.

If your fleet outsources its tire maintenance, and therefore such maintenance is expensive and can lead to extended downtime, then these additional costs should be considered if you decide to invest in low rolling resistance tires.

5. Keeping the tires a correct pressure

Any reduction in resistance (and therefore savings) offered by low rolling resistance tires are negated if they are not kept at the proper inflation.

Although it seems trivial, a study by Continental found that 34% of fleet drivers drive on underinflated tires regularly.

Before you choose to invest in low rolling resistance tires, you must make sure that proper driver education and accountability is in place. Vehicle tracking systems can monitor driver behavior to help you ensure that your vehicles are being driven sensibly, without undue stress on the tires.

In addition, you can hold staff responsible for keeping their tires fully inflated. Such accountability procedures can include: regular spot checks for correct tire pressure between routes and keeping a log book of tire pressure tests between journeys.

Wrapping up

Low rolling resistance tires are an investment in your fleet, and due diligence is needed to work out whether you are likely to get a good ROI from this.

Since these tires are more expensive than standard ones, it is vital to put procedures in place to ensure that the tires are kept in the best condition to ensure that you will derive the desired benefits from them throughout the duration of their use.